PARTING AND GROOVING HOLDERS

PARTING AND GROOVING HOLDERS Specification

- Cutting Force

- High

- Coating

- Available with or without Coating

- Length

- Standard and Custom Lengths

- Features

- Rigid Design, Precise Clamping, High Stability

- Hardness

- Up to 60 HRC (Holder Body)

- Cutting Speed

- Depends on Insert, Up to 200 m/min

- Operate Method

- Manual/CNC

- Shape

- Rectangular/Customized

- Cutter Type

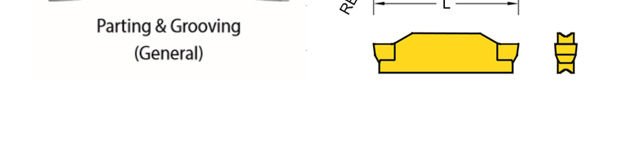

- Parting and Grooving Tool Holder

- Cutting Capacity

- Varies by Insert Size

- Material

- Alloy Steel/Carbide

- Cutting Accuracy

- High Precision

- Machine Type

- CNC Lathe, Automatic Lathe, Manual Lathe

- Coating Type

- Uncoated/Coated (Depending on Application)

- Operation Type

- External Grooving/Parting

- Tool Type

- Parting/Grooving Holder

- Diameter

- Holders Suited for Various Insert Widths (Usually 2mm to 6mm)

- Maximum Torque

- Depends on Machine Specification

- Processing Type

- Turning, Grooving, Parting Off

- Insert Compatibility

- Compatible with Standard ISO Grooving/Parting Inserts

- Coolant Supply

- Internal/External Coolant Options

- Application

- Parting and Grooving Operations on Bar Stock and Tubing

- Corrosion Resistance

- Yes, Depending on Surface Finish

- Clamp System

- Screw or Lever Clamping Depending on Model

- Mounting Type

- Shank (Square or Round) Mounting

- Body Finish

- Black Oxide/Polished

- Packing Type

- Individual Plastic Box/Carton

PARTING AND GROOVING HOLDERS Trade Information

- Minimum Order Quantity

- 10 Pieces

- FOB Port

- MUMBAI

- Payment Terms

- Cash Against Delivery (CAD), Cash on Delivery (COD), Delivery Point (DP), Cash in Advance (CID), Cheque, Cash Advance (CA)

- Supply Ability

- 100 Pieces Per Day

- Delivery Time

- 4 Days

- Sample Policy

- Sample costs shipping and taxes has to be paid by the buyer

- Main Export Market(s)

- Middle East, Asia

- Main Domestic Market

- All India

About PARTING AND GROOVING HOLDERS

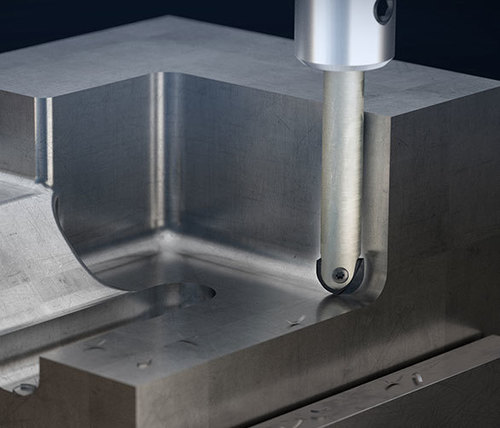

Parting and grooving methods

Parting

When parting, bar components are parted off. This method is used particularly often for mass production.

Grooving

When grooving, grooves are produced in the component; this can happen both radially as well as axially.

Parting, grooving and turning

For the production of very wide and shallow grooves, the longitudinal turning method is the most often used, as it saves valuable time and, as a result, also costs.

Profile grooving

With profile grooving, a special profile is produced using a radius insert.

Deep grooving

In order to produce very deep grooves, when applying this method, a blade is most commonly used.

Types

Modular parting and grooving system

Monobloc tool

Block/blade solution

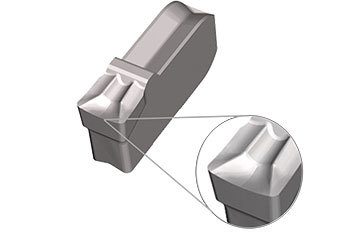

Unmatched Precision for Turning Applications

Experience high cutting force and accuracy with our parting and grooving tool holders, purpose-built for external grooving and parting off on a variety of lathes. Their rigid construction and reliable clamping deliver stability, even under demanding machining conditions. Compatible with a broad range of ISO inserts, these holders support versatile bar stock and tubing applications, optimizing productivity for Austrian distributors, service providers, and wholesalers.

Flexible Mounting and Customization

Choose from square or round shank mounting options, allowing seamless integration into CNC, automatic, or manual lathes. Our holders are available in rectangular or custom shapes, with diameters suitable for insert widths from 2mm to 6mm, and lengths tailored to your requirements. The durable alloy steel or carbide constructionup to 60 HRC hardnessensures long-lasting performance, while coated or uncoated finishes meet specific operational demands.

FAQs of PARTING AND GROOVING HOLDERS:

Q: How are these parting and grooving holders mounted on machines?

A: The holders feature shank mounting optionseither square or roundand are designed for seamless installation on CNC, automatic, or manual lathes used in turning operations.Q: What cutting insert compatibility do these holders offer?

A: They are fully compatible with standard ISO grooving and parting inserts, allowing for efficient use of industry-standard tooling and flexibility in sizing from approximately 2mm to 6mm widths.Q: When should I use internal versus external coolant supply?

A: Use internal coolant supply for enhanced cooling efficiency, especially during high-speed or high-precision cutting. External coolant is suitable for less demanding jobs or when internal supply is unavailable, helping reduce tool wear and improve chip evacuation.Q: Where can I source these tool holders in Austria?

A: These parting and grooving holders are available through local distributors, service providers, suppliers, traders, and wholesalers across Austria, with packaging options including individual plastic boxes or cartons for secure delivery.Q: What is the process for selecting the right holder for my application?

A: Consider your machine type, insert size, required cutting capacity, shank shape, and whether you need coated or uncoated finishes. Our team can advise on customization for specific turning, grooving, or parting operations.Q: What usage benefits do these holders provide?

A: You gain high cutting accuracy, precise and rigid clamping, and reliable corrosion resistance. This results in improved overall tool life, operational stability, and consistent performance during external grooving or parting off on a range of lathe machines.Q: How does surface finish affect corrosion resistance and longevity?

A: Black oxide and polished finishes are available, offering varying degrees of corrosion resistance. Choosing the appropriate finish enhances protection against wear, extending holder durability, especially in demanding machining environments.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Indexable Carbide Tools Category

U-DRILLS

Price Range 300.00 - 2000.00 INR / Piece

Minimum Order Quantity : 10 Pieces

Material : Carbide

Shape : Cylindrical

Coating : TiN (Titanium Nitride)

I-XMILL

Price Range 1000.00 - 3000.00 INR / Piece

Minimum Order Quantity : 10 Pieces

Material : Carbide

Shape : ROUND / BALL / FLAT

Coating : CVD / PVD

Thread mills

Price Range 2000.00 - 20000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Material : Carbide, High Speed Steel

Color : Silver

Face Milling Carbide Inserts

Price Range 300.00 - 900.00 INR / Piece

Minimum Order Quantity : 10 Pieces

Material : Carbide

Shape : ROUND, SQUARE, RECTANGLE, HEXAGON, OCTAGON

Coating : PVD,CVD,HYPER,BLUE

Branch Office:

A2/10, Brij Industries, 109 1st Floor,

GIDC, Makarpura, Badodra - 3900010

Mobile: +918000931330.

Send Inquiry

Send Inquiry